From Jeff Hannah, VP of International, Commercial Interiors, & Creative

We often get questions about Domestic Exhibiting Costs & International Exhibiting Costs and why they can vary so drastically. Here’s the best way to understand the differences- and why U.S. exhibiting costs tend to be higher in comparison.

We’ve recently started exhibiting internationally, and compared to crafting a similar experience in the United States, international exhibiting is downright cheap! Why are U.S. exhibiting costs so high?

Exhibit marketing is a fairly complex endeavor involving everything from transportation and drayage to design and fabrication. Multiple companies, each with their own policies, rules, and fees, provide products and services within each of the industry’s unique aspects. Therefore, explaining what may be driving up the price of exhibiting is just as complex as the industry itself. Plus, the economics of every country play a role in how much services, products, and labor cost, which in turn affect the price of exhibiting. That said there are generally three factors that elevate the price to exhibit at U.S. shows over similar events in other countries: segmentation/location, unions, and industry sophistication.

Segmentation/Location

The U.S. exhibit industry is segmented into multiple areas of specialization, more so than in many other countries. Plus, the distance booths travel to and from shows is typically far less in other parts of the world. Thus, factors related to transportation and segmentation often result in higher fees.

Most international exhibit builders craft exhibits in their own shops, sometimes only partially constructing a one-time use structure that is later fully completed on the trade show floor. These same firms often transport the exhibits from their shops directly to the venues, rather than hiring outside trucking companies. And since these are typically temporary builds that will only be used once or twice, as opposed to over the course of several years, the exhibit components are minimally secured for transport and not housed in heavy crates or customized shipping containers.

What’s more, many international exhibit builders produce stands that will be used at nearby venues, which means they’re often transporting booths across a city or regional area as opposed to across a country the size of the United States. Finally, once on site, the same exhibit-building firms frequently install their own exhibits, as opposed to hiring separate installation-and-dismantle (I&D) companies — a factor that not only saves money but often saves time, as exhibit houses can usually install their own exhibitry far faster than labor crews that are viewing the setup plans for the first time.

In the United States, however, an exhibit house typically constructs a sturdy and often heavy exhibit that will be used multiple times over the course of several years. It’s then securely crated for long-distance transport. Then, the exhibit house hires a freight carrier to transport the booth to the show, which could be literally thousands of miles away. When it arrives at the event, it is assembled by a labor crew (either an exhibitor-appointed installation firm or general contractor labor) that many times isn’t employed by the original exhibit house.

Thus, in the United States, there are multiple players involved, each of which comes with a fee aside from the design and construction of the booth. And often, if the exhibit house hires such a firm on your behalf, you’re also paying a markup on the original cost of the service. In addition, exhibits usually travel greater distances from the exhibit house to a show in the United States than they do in many international locales. Bottom line: international exhibitors typically pay a turnkey fee to an exhibit house for a booth at a specific show; whereas, U.S. exhibitors pay an exhibit house, transportation firm, drayage provider (more on that later), and an I&D company. The sum of all companies’ fees is typically greater than the total amount for a single international exhibit house to perform the same functions. Add in the transportation fees — as well as the following factors — and you’ve racked up a hefty bill.

Unions

Unlike most other countries, I&D labor in the United States often falls under union jurisdiction. So not only are you paying for an independent or general contractor to install your booth (using exhibit components that laborers are usually seeing for the first time when they step on the show floor), but also their rates are generally higher due to union mandates. Additionally, tight regulations govern union workers’ actions. For example, union rules stipulate how many hours laborers can work per day, the standard rates being charged, when overtime rates apply, and when there are four-hour minimums that you must pay (even if workers only spent an hour in your booth). Furthermore, labor unions often maintain exclusive control over certain types of work activities in various venues, such as drayage, cleaning, rigging, decorating, cleaning, running electrical wiring, etc. As such, this exclusive control drives costs higher due to a lack of competition and alternative choices.

In comparison, most overseas contractors aren’t under union jurisdiction and as such pay rates and hours worked are far more flexible — a factor that results in decreased costs for exhibitors. Plus, the majority of international exhibit houses offer a fixed fee to produce a turnkey exhibit, including labor, transportation, material handling, etc. Unless clients make major changes along the way, they pay the exact cost that was stipulated prior to the beginning of the exhibit build. Regardless of how long it takes laborers to install your stand, you will be paying the same amount you originally agreed upon. This practice eliminates extra fees for overtime charges, unexpected snafus, and ineffective or inefficient laborers.

Industry Sophistication

Simply put, countries where the exhibit industry is mature and more sophisticated tend to have higher costs than those where the industry is less developed. That’s because greater sophistication often results in higher-quality exhibits, and the designs, materials, crates, etc. associated with these stands cost more than lesser-quality booths.

In addition, custom U.S. exhibits are usually built as multiuse properties that are used for three or more years. Many of them are at least partially modular, allowing for easier transportation and I&D than fully custom builds. However, almost any degree of modularity requires specialized connectors, panels, flooring pieces, etc. In contrast, exhibits built overseas are more frequently single-use “build and burn” stands that are used for only one show. They are constructed to withstand a single, often one-way transport to the event and three or four days (not three or four years) of wear and tear. As such, their structural quality can be much lower, and thus, their costs are similarly decreased.

So in the United States, everything from materials and levels of industry sophistication to the presence of unions and multiple supplier fees drive up the price of executing a face-to-face marketing program. But it’s kind of an, “It is what it is” situation. While international exhibitors building booths in the United States experience pretty severe sticker shock, U.S. exhibit professionals are fairly used to their unfortunate hurdles — and they typically exhale a big sigh of relief when they get their international-exhibiting invoices.

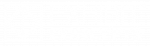

This article originally appeared in the November, 2017 issue of EXHIBITOR magazine.